Fabrication of freeform optical components by fluidic shaping

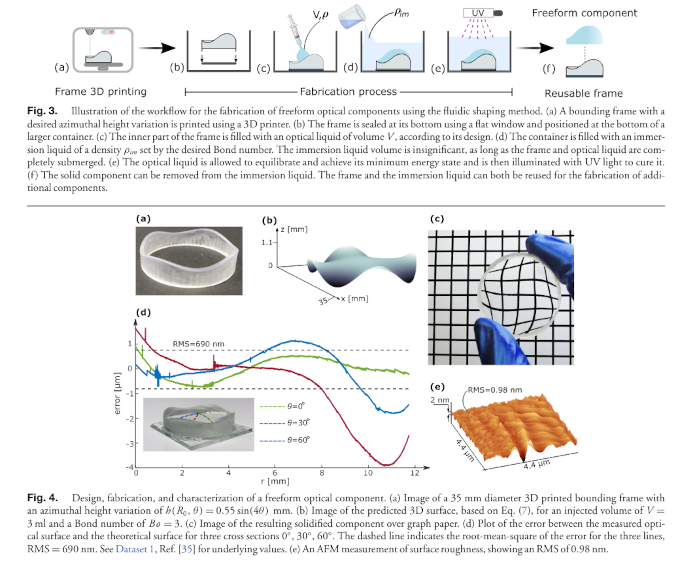

"Freeform optical components enable advanced manipulation of light that is not possible with traditional optical systems. However, their fabrication relies on machining processes that are complex, time-consuming, and require significant infrastructure. Here we present the ability to shape liquid volumes and solidify them into desired freeform components, enabling rapid prototyping of freeform components with high surface quality. The method is based on controlling the minimum energy state of the interface between a curable optical liquid and an immersion liquid, by dictating a geometrical boundary constraint. We provide an analytical solution for the resulting topography given a predefined boundary and demonstrate the fabrication of freeform components with sub-nanometer surface roughness within minutes. Such a fabrication capability, that allows for rapid prototyping of high-quality components, has the potential to answer an unmet need in the optical design industry—allowing researchers and engineers to rapidly test freeform design concepts. It can be further envisioned to be expanded to an industrial scale, allowing for mold-less fabrication of freeform optics."

Criado/Created: 19-11-2021 [08:33]

Última actualização/Last updated: 09-10-2023 [15:52]

(c) Tiago Charters de Azevedo